Page History: Clamshell Cutterheads

Compare Page Revisions

Page Revision: 2008/04/06 22:59

Introduction

Many older jointers utilized a style of cutterhead now known as "clamshell". This style of cutterhead is no longer utilized by modern manufacturers due to safety issues.

Safety Issues

The problem with a clamshell head is that the knives are directly held in place by the bolt heads. The faster the head spins, the higher the stress on the bolt heads. Hit a knot, and the impact transfers directly to the bolt heads. Now, are the bolts original, never been over-tightened, no stress cracks where the heads meet the stems, made of top-quality steel that was accurately machined and properly heat treated? If you are confident of good answers to all those questions, then your clamshell head should be plenty safe. Otherwise, you are taking chances.

SourceNot only are the knives held in directly by the bolts, but the caps which pinch the knives are also held down by the bolts. The caps are heavy, and under the same forces as the knives. When a bolt fails, usually at one end, the cap bends, hitting the infeed table with considerable force. To reinforce the dangers of clamshell heads, There have been at least three accidents mentioned on the OWWM forums in recent years.

Example of damage from a failed Clamshell Head |

Do you have the kind of equipment that can evaluate the condition of the bolts? Do you know they have never been over-tightened? Are you sure you have all of them sufficiently tight? Are you sure that the bolts are tightening on the caps and not bottoming out in their holes? Unfortunately, clamshells are accidents waiting to happen. Some of us have used them for years, but statistically speaking, the longer you run one, the more chance there is of that accident happening.

Jeff Smith provided more information here

http://owwm.org/viewtopic.php?t=29825 on bottoming out of the bolts on a cutterhead. One of the issues with a clamshell head is "bolt stretch" allowing the bolts that secure the blades to bottom out and giving one a false sense of tightness.

Clamshell disasters are discussed here

http://www.owwm.org/viewtopic.php?t=28690 and here

http://owwm.org/viewtopic.php?t=22268

Clamshell Bolts

Another wide-ranging discussion of clamshell issues such as bolt head size, torque, use of loctite, etc. here

http://owwm.org/viewtopic.php?t=31531Examples of Clamshell Heads

Ray Munro and Kirk Poore posted a number of photos of jointer clamshell heads here

http://owwm.org/viewtopic.php?t=28844

Oliver Clamshell in the front of this picture

Side view showing the cap. Oliver Clamshell is on the left (wood filler substituting for the knife). SCMI replacement head on the right (with knives in backwards so I do not cut myself)

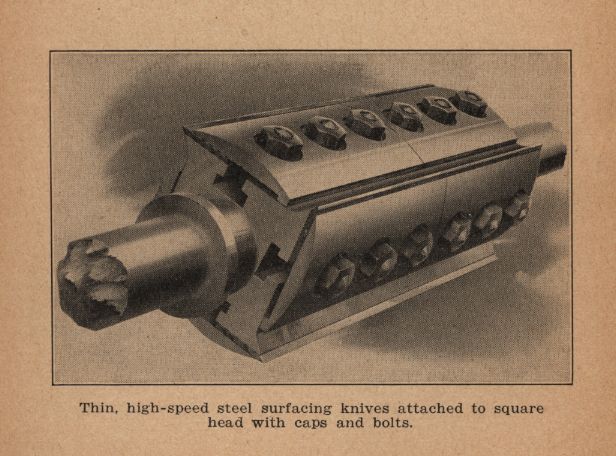

Here is a picture of a square head that is set up to use thin (non slotted knives) with knife caps. The knives are retained by the cap, not the bolts directly. Could be called a "clamshell" I guess.

Here is a "Stutzman" head. It can be used as a square head, with slotted knives, or with caps that clamp the knives.

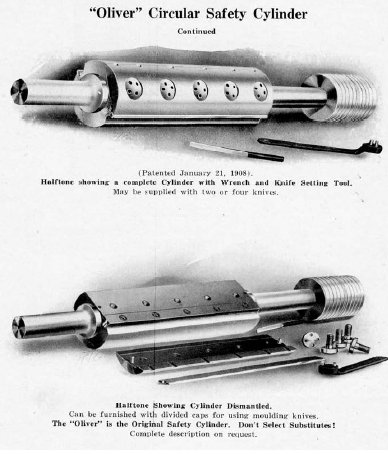

Clamshell illustration from an Oliver Catalog.

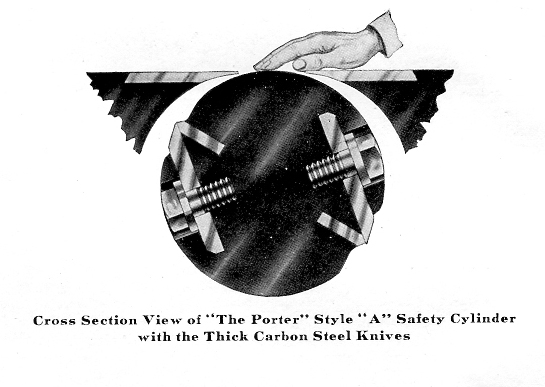

Porter Style "A" safety cylinder

The Porter Style "A" safety cylinder uses a slotted knife and has an unsupported "cap" portion that gives the head a cylindrical profile. The Porter had a replaceable wear strip/chip breaker located at the cutting edge of the knife. The Oliver head incorporated a similar replaceable strip that served as the knife seat and chipbreaker.

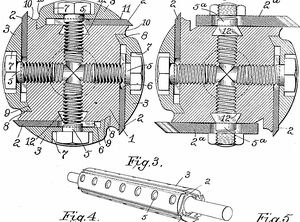

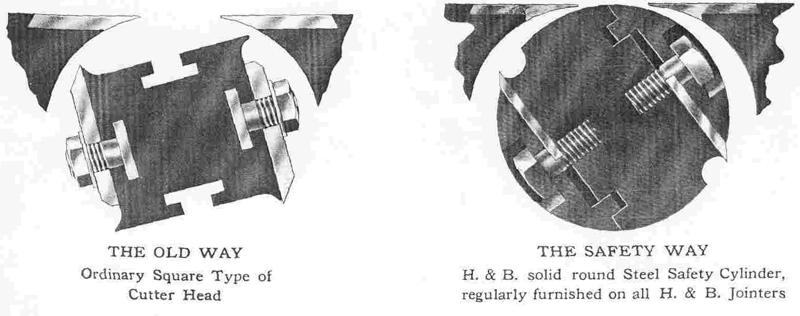

Cross section diagram of a Hall & Brown clamshell, contrasted with a square head.