by Bob Vaughan

Introduction

Naturally, blades joined in this manner won't worn on NWWM :-) The JK Woodcraft jig shown is a prototype from 1987. The newer ones are galvanized and don't rust up as easily.

How you grind the scarf joint is up to your using what faculties you have. I like this rig better than any other I've tried because it keeps that thorny snake of a bandsaw blade off my shoulders and more at my feet.

Not shown is what to do if there's ticking as the blade runs through the guides from a high spot. Color the blade with a felt tipped marker, roll the blade through a few revolutions, observe where the color has worn away and get out the dremel and grind down those spots.

Photos

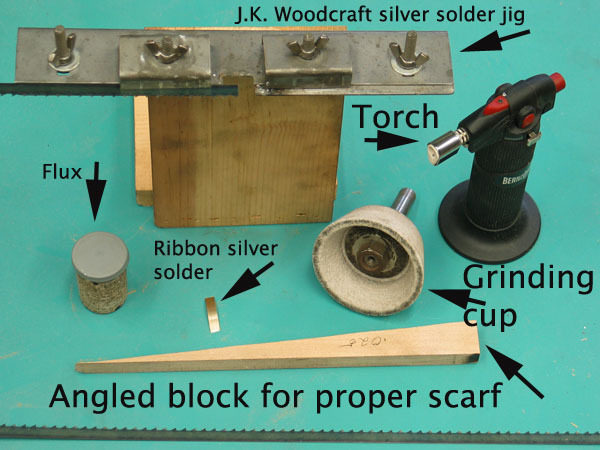

Components |

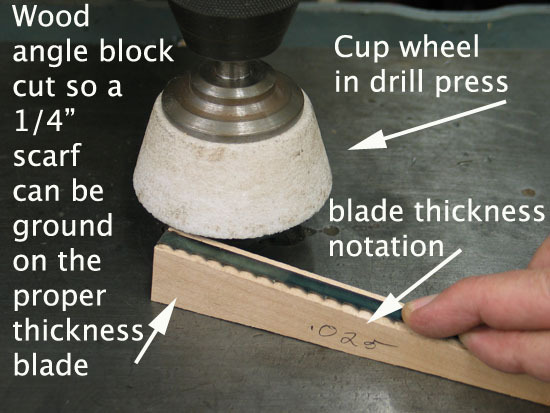

Grinding Block |

Grind Scarf |

Ground Scarf |

Ground Scarf Joints |

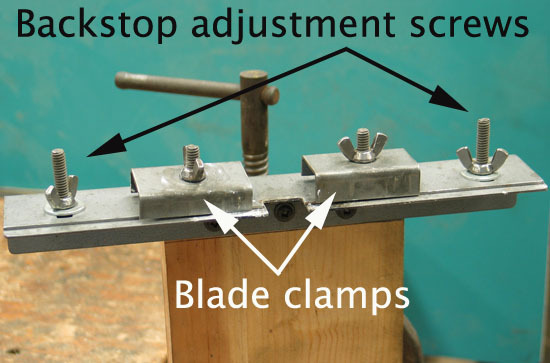

Holder |

Clamp to bench |

Set jig for blad size |

Center the ground area in the slot |

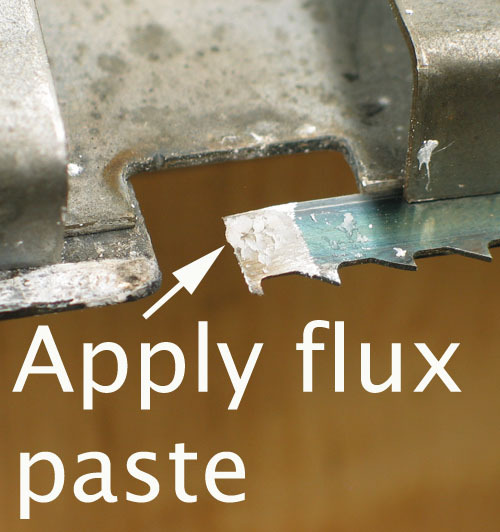

Apply Flux |

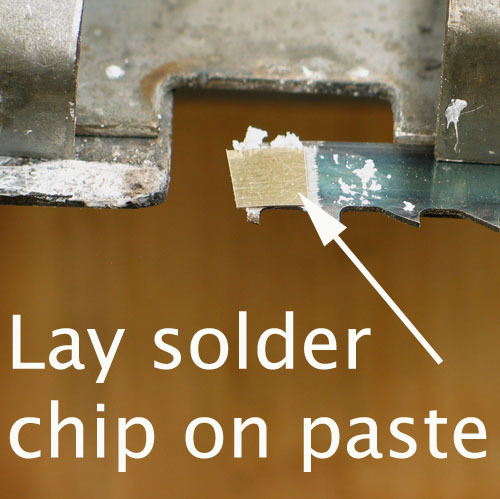

Apply Solder |

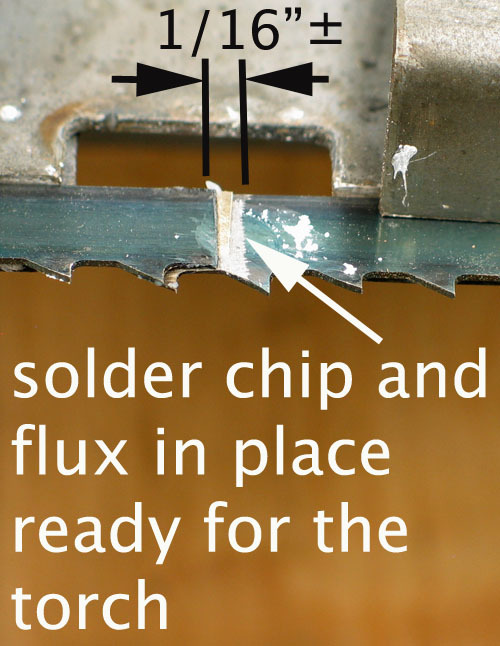

Ready for the torch |

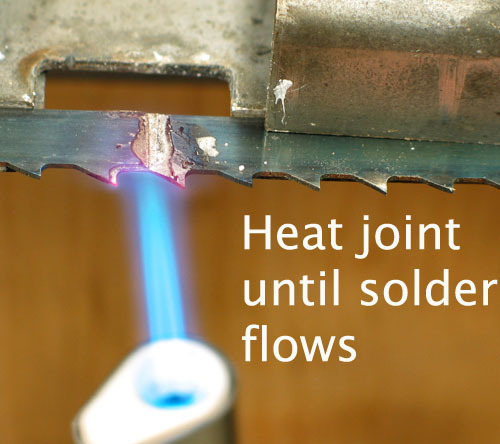

Heat Joint |

Cool joint |

Get ready to grind |

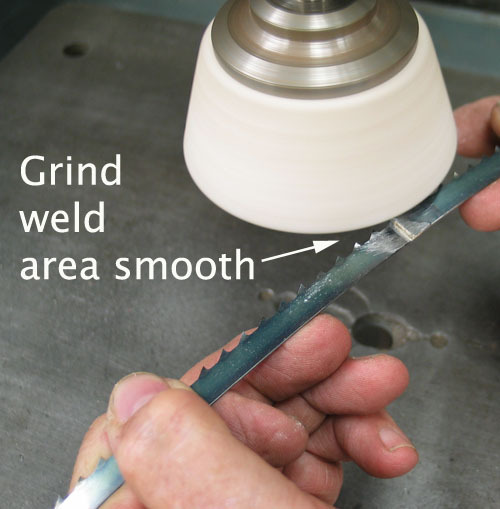

Grind |

Color ground area |

That's all there is to it!